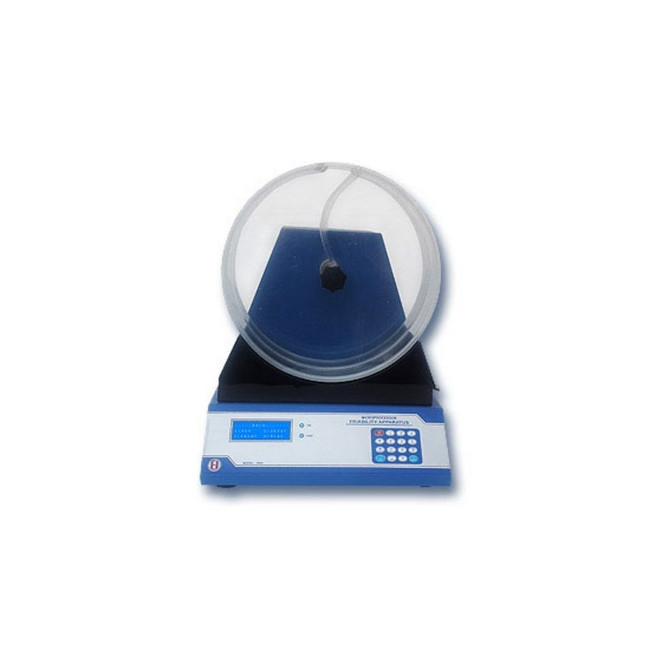

Product Overview:

The Microprocessor Friability Apparatus, Model 1902, is a precision instrument engineered to measure the tendency of pharmaceutical tablets to chip or break down when subjected to mechanical stresses. This instrument utilizes the latest microcontroller technology and advanced engineering techniques, ensuring enhanced accuracy and reproducibility for critical quality control and research applications. It is compliant with internationally recognised USP and IP specifications, making it suitable for use in pharmaceutical laboratories and institutions.

Advanced Microprocessor Control:

This friability tester is microprocessor based and designed for user-friendly operation. The system is equipped with a 20 x 4 line alphanumeric LCD display with backlit visibility, facilitating easy reading and monitoring of current status indicators and menus. Input control is managed via 16 soft touch membrane type keys, functioning as an alphanumeric mobile keypad. Users benefit from independent programmable setups for both Time mode and Count mode, which include internal storage capabilities for test parameters, readings, and results. These stored results are retained even after the instrument is powered off.

Automated Testing and Data Handling:

The Model 1902 offers several features designed to streamline the testing process and improve data integrity:

• Double Drum Design: The apparatus typically operates with two drums, although it can be run using only one.

• Convenient Sample Management: Samples can be loaded and unloaded conveniently without the need to remove the drums. After testing completion, the samples are automatically unloaded to a collection tray.

• Automatic Calculation: The instrument automatically calculates the percentage friability of the tested tablets.

• Weighing Balance Connectivity: To eliminate the need for manual weight input, the instrument includes a facility to connect an external weighing scale. When connected, the weight of the samples is automatically recorded to the instrument directly from the balance.

• Printing Capability: Provision is made for the attachment of an RS232 printer with a Serial interface, allowing for hard-copy printouts of all test data, including time, date, and calculated results.

Operational Security and Reliability:

The instrument is built with features focused on security and continuous operation, including password-protected user access to maintain data integrity and control settings. Furthermore, it incorporates a Power Failure detection facility to safeguard test continuity and data under unstable electrical conditions. The drive system uses a Direct Drive with Stepper Motor, enabling precise control over the rotational speed of the drums.

Technical Specifications:

|

Specification

|

Detail

|

|

Model

|

1902

|

|

Test Methods

|

Time and Count Mode

|

|

No. of Drums

|

2

|

|

Speed of Drums

|

20 – 60 RPM

|

|

Display

|

20x4 Alphanumeric LCD

|

|

Keyboard

|

Soft touch membrane keys, alphanumeric mobile keypad

|

|

Counter Range

|

1 to 9999 rotations

|

|

Timer Range

|

1 second to 9 hours 59 minutes 59 seconds

|

|

Type of Drive

|

Direct Drive with Stepper Motor

|

|

Printer Interface

|

Attachment of RS232 printer with Serial interface

|

|

Electrical Supply

|

230 V AC ± 10%, 50/60 Hz, 44VA

|

|

Dimensions (WxHxD)

|

335mm X 330mm X 340mm

|

|

Weight

|

12 Kgs

|